- This topic is empty.

-

AuthorPosts

-

21/07/2025 at 18:29 #5339

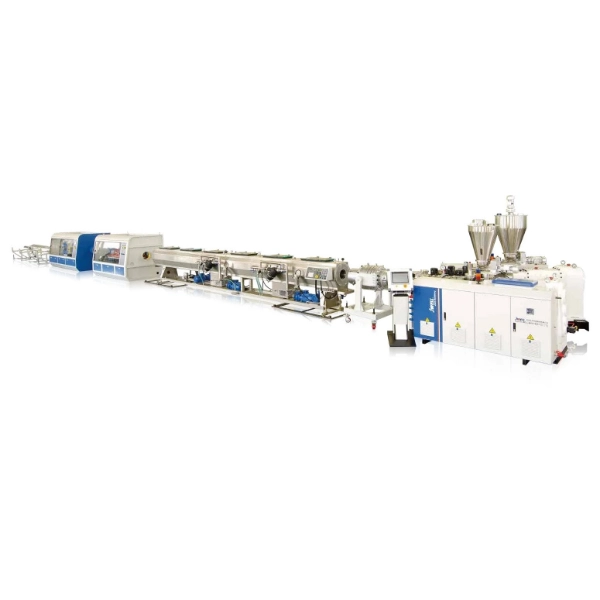

The manufacturing of polyvinyl chloride (PVC) pipes has seen significant innovation over the years, with twin-pipe extrusion systems leading the charge for increased efficiency and reduced operational costs.Among the most advanced systems in this domain is the Jwell Extruder Machine. This high-performance production line is designed to simultaneously extrude two pipes, optimizing both space and output in industrial PVC pipe manufacturing operations. As high performance Jwell PVC extruder exporter, in this blog post we will share the benefits of Jwell PVC dual pipe extruder machine for sale.

Jwell PVC Dual Pipe Extruder Machine Benefits

1. Twin-Screw Extruder Flexibility: Configurations for Various Needs

The Jwell PVC dual pipe extruder offers two main extruder configurations: SJZ80 and SJZ65 special twin-screw extruders. These options correspond to different production requirements based on pipe diameter and desired output.

* SJZ65 Model: Suitable for medium-scale production lines and smaller pipe diameters, it provides an ideal balance between compact footprint and extrusion capacity.

* SJZ80 Model: Designed for larger output and wider diameter PVC pipe production, this configuration delivers higher torque and greater extrusion force.

The twin-screw design ensures superior material mixing, melting, and plasticization, essential for producing high-density, homogeneous PVC pipes. Whether manufacturing pressure pipes for irrigation or non-pressure conduits for electrical applications, users can configure the machine based on specific throughput demands.

2. Dual Pipe Die for Balanced and Stable Output

A critical innovation in the Jwell system is the dual pipe die head, which evenly distributes molten PVC to both extrusion channels. This architecture offers several advantages:

* Simultaneous Pipe Production: Instead of producing one pipe at a time, manufacturers can extrude two identical pipes in parallel, effectively doubling productivity.

* Stable Output Flow: Even distribution eliminates flow irregularities that may lead to pipe deformities or uneven wall thickness.

* Quick Plasticization: The high-performance die design supports rapid material conversion, which accelerates overall line speed without sacrificing pipe quality.

This feature is particularly valuable for manufacturers seeking high-volume output with stringent dimensional accuracy.

3. High-Efficiency Double-Vacuum Cooling System

After extrusion, the molten PVC pipes require rapid and uniform cooling to maintain structural integrity. The Jwell dual pipe extrusion line addresses this with a double-vacuum cooling tank, a system capable of independent operation for each pipe.

* Separate Control: Each vacuum chamber can be individually adjusted, allowing different cooling parameters for each pipe — beneficial for customized pipe specifications.

* Improved Cooling Efficiency: The dual-vacuum design increases the contact surface area and airflow stability, ensuring consistent diameter and roundness.

* Operational Convenience: The adjustment mechanisms are designed for easy access and rapid changeovers during production runs.

By optimizing the cooling process, this feature reduces cycle time and minimizes the risk of internal stress or cracking in the final product.

4. Dustless Cutting and Chamfering for Precision Finishing

Finishing is a vital part of the extrusion process, and the Jwell system integrates an advanced dustless cutting machine with impressive precision and speed.

* Double Station Independent Control: Each pipe can be cut at different lengths without interference, providing flexibility in batch processing.

* Fast and Accurate Cutting: High-speed servo control ensures precise cutting lengths, minimizing material waste and eliminating the need for secondary trimming.

* Pneumatic Clamping System: With pneumatically rotating clamps, the machine can automatically adapt to different pipe sizes without manual clamp replacement, greatly improving workflow efficiency.

* Optional Chamfering Device: For applications requiring smooth pipe ends, the integrated chamfering module ensures clean, angled edges ready for direct connection or socket welding.

This suite of features enhances productivity and ensures that the final product meets both aesthetic and mechanical standards.

5. Automation and Intelligent Control

The Jwell PVC dual pipe extrusion line incorporates intelligent PLC (Programmable Logic Controller) systems with user-friendly interfaces. Operators can monitor the full process, including extrusion temperature, motor load, vacuum level, cutting length, and cooling temperature.

* Real-Time Monitoring: Ensures consistent quality and helps operators respond swiftly to deviations.

* Recipe Management: Enables quick switching between pipe specifications.

* Energy Efficiency: Optimal control minimizes energy usage while maximizing output.

The automation system also includes fault alarms and protection protocols, safeguarding the machine and improving operational uptime.

6. Space-Saving and Cost-Efficient Production

By combining dual pipe extrusion with integrated downstream units, the Jwell system offers a compact and streamlined layout. This reduces the required factory footprint and facilitates easy integration into existing production lines.

Additional cost benefits include:

* Lower Per-Unit Production Cost: Doubling the output with only marginal increases in energy and manpower leads to significant cost savings.

* Reduced Material Waste: Precision extrusion and cutting ensure material is used efficiently.

* Faster ROI: Due to higher throughput and reduced downtime, manufacturers see quicker returns on investment.

7. Durability and Long-Term Stability

Constructed with high-grade stainless steel and alloy components, the machine ensures long service life, corrosion resistance, and mechanical stability under continuous high-load conditions.

* Hardened Gearbox and Bearings: Ensures long-term reliability in continuous operations.

* Corrosion-Proof Design: Ideal for processing PVC, which may contain corrosive additives like chlorine or calcium compounds.

* Low Maintenance Requirement: Simplified component design reduces the need for frequent servicing, further decreasing operational downtime.

Conclusion:

The Jwell PVC Dual Pipe Extruder Machine exemplifies modern extrusion technology tailored to meet the growing demands of the plastic pipe industry. With dual-extrusion capability, advanced automation, precise control, and robust mechanical design, this machine provides:

* Higher productivity

* Reduced energy consumption

* Enhanced product quality

* Greater operational flexibility

Whether for civil engineering, electrical conduit, water supply, or drainage systems, the Jwell dual pipe extrusion line empowers manufacturers to stay competitive in today' s fast-paced market. For companies seeking to scale production while maintaining strict quality standards, investing in this state-of-the-art system is a strategic move with long-term benefits.

http://www.jwellplas.com

JWELL -

AuthorPosts

- You must be logged in to reply to this topic.