- This topic is empty.

-

AuthorPosts

-

07/01/2026 at 14:24 #6909

https://www.goldenabrasives.com/Green-abrasive-film

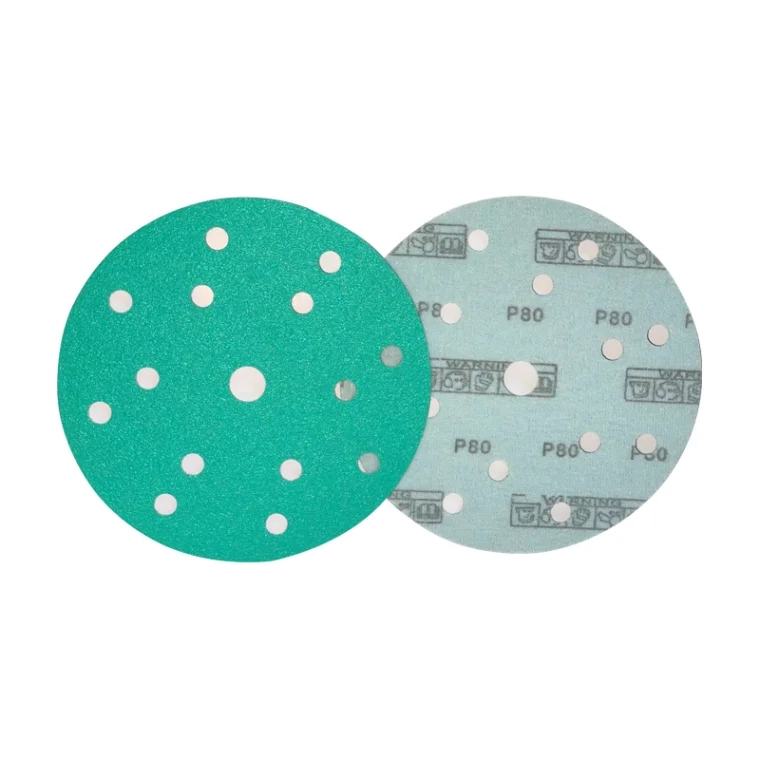

In high-end manufacturing environments where finishing accuracy directly determines product quality, the materials used for surface correction and refinement must deliver uncompromising consistency. Among the diverse abrasive options available today, green abrasive film has steadily become a preferred choice due to its stability, precision, and predictable cutting behavior. Instead of relying on traditional paper-based abrasives that fluctuate in performance based on humidity and pressure, technicians and engineers are increasingly turning to film-backed abrasives for sophisticated finishing tasks that require measurable accuracy.

Green abrasive film is different from conventional abrasives not simply because of its appearance or color, but because of the engineering discipline behind its structure. The tight mineral grading, polymer-based backing, and controlled bonding layer create a uniform abrasive surface capable of achieving micro-level refinement even under demanding conditions. High-performance products such as Golden Abrasives green abrasive film exemplify how modern abrasive film solutions support technicians in achieving consistent surface results across long production cycles.

Understanding the Inner Engineering of Green Abrasive Film: What Makes It So Uniform and Predictable?

Green abrasive film is more than an abrasive sheet—it is a carefully engineered system designed to maintain geometric stability, deliver predictable cutting performance, and withstand extensive friction. Its performance characteristics originate from three foundational components: the abrasive grains, the polymer film backing, and the bonding resin system.

Micro-Precision Mineral Grading for Superior Cutting Stability

The abrasive grains in green abrasive film undergo advanced classification using optical sorting and density-based separation. This ensures that every grain falls within a narrowly defined size and shape distribution. Such precision dramatically influences the final surface result because inconsistent grain shapes generate uneven scratching, deeper score marks, and unpredictable material removal rates.

In high-precision environments—such as automotive refinishing, aerospace composite finishing, and high-gloss wood preparation—this grading precision becomes critical. When technicians transition from one grit level to the next, the consistent mineral structure of green abrasive film ensures that scratch patterns remain uniform across the entire surface. That uniformity reduces the number of corrective passes required and stabilizes downstream polishing operations.

Dimensional Stability Through Polymer Film Engineering

The backing used in green abrasive film is engineered from high-tensile polymer film instead of traditional paper. This upgrade prevents the abrasive from swelling, warping, tearing, or losing geometric alignment when exposed to heat, pressure, or humid conditions. As a result, the film maintains a perfectly flat and stable sanding surface under various mechanical loads.

This stability is particularly important in automated finishing systems or rotary sanding operations where even slight deformation can disrupt the consistency of the final surface. A well-constructed green abrasive film ensures that technicians can rely on precise contact angles, predictable grain engagement, and sustained abrasive exposure throughout the product's lifespan.

A practical example of this level of engineered stability can be seen in the design of Golden Abrasives green abrasive film. Their film-backed abrasives utilize a high-tensile polyester structure that resists warping, tearing, and dimensional distortion even under continuous heat and pressure cycles. Combined with tightly graded zirconia minerals and a clog-resistant coating, the discs maintain uniform grain engagement across curved, flat, or mechanically complex surfaces. This construction allows Golden Abrasives green abrasive film to deliver consistent cutting behavior throughout extended production runs, making it suitable for both manual finishing tasks and high-duty automated sanding systems where precision and repeatability are essential.

High-Performance Resin Systems for Extended Grain Retention

The bonding resin acts as the structural interface between the abrasive particles and the film backing. High-end green abrasive film products use resin systems formulated to resist thermal softening, chemical interference, and mechanical fatigue. When the bond maintains integrity, abrasive grains remain anchored longer, meaning the initial sharpness of the film continues through extended usage.

Resins also influence grain exposure angles. If the bond is too rigid, grains may break prematurely; if too flexible, grains may embed deeper into the surface and reduce cutting aggression. High-precision resin engineering ensures a balanced interaction between sharpness, durability, and heat dispersion.

How Green Abrasive Film Performs on a Microscopic Level: The Science of Controlled Cutting

To fully appreciate the technological achievement behind green abrasive film, it is necessary to understand the physics of abrasive interactions. When abrasive grains engage a surface, several micro-phenomena occur simultaneously.

To fully appreciate the technological achievement behind green abrasive film, it is necessary to understand the physics of abrasive interactions. When abrasive grains engage a surface, several micro-phenomena occur simultaneously.Predictable Scratch Patterns Built on Geometric Consistency

Each grain in a green abrasive film acts like a mini cutting tool with a fixed orientation. When grains share similar geometry and are coated at consistent spacing intervals, the scratch pattern they generate exhibits a tightly controlled depth and direction. This is crucial when preparing surfaces for coatings, bonding, laminating, or high-gloss finishing, where any irregular scratch may telegraph through subsequent layers.

The repeatability of green abrasive film ensures that technicians can depend on stable surface profiles from the first pass to the last. This stability reduces operator variability and enhances the precision of the entire finishing sequence.

Controlled Cutting Pressure for Sensitive and Hard Surfaces

A distinguishing feature of green abrasive film is its ability to adapt its cutting force across various materials. Hard surfaces such as aluminum or carbon fiber require sharp, stable minerals that resist fracturing under pressure. Meanwhile, softer materials like plastics and clear coats benefit from a controlled cutting pressure that prevents gouging.

The engineered structure of green abrasive film allows it to maintain the necessary balance, ensuring efficient material removal without excessive surface disruption.

Optimized Heat Reduction Through Grain Spacing and Film Flexibility

Excessive heat is a primary cause of abrasive clogging, resin degradation, and substrate damage. Green abrasive film combats heat accumulation using:

-

precisely spaced abrasive grains

-

heat-stable resin structures

-

flexible film that conforms to micro-contours

-

uniform cutting engagement without deep plowing

This optimized thermal performance extends the life of the abrasive and preserves the integrity of the workpiece.

Why Precision Finishing Workflows Benefit From Green Abrasive Film Integration

When a workshop evaluates its sanding workflow, consistency is the most important factor. Green abrasive film elevates process stability in several ways.

Smoother Multi-Grit Transitions and Reduced Process Variability

A structured sanding workflow often relies on numerical grit progressions to gradually refine a surface. When each grit behaves predictably, technicians achieve consistent surface roughness values and avoid micro-scratches that require reworking.

With green abrasive film, each step becomes easier to control due to its consistent grain distribution and reliable cutting geometry. This directly contributes to a refined finishing sequence with fewer correction cycles.

Lower Rework Rates and Higher Productivity

Rework is one of the largest hidden costs in finishing departments. Unpredictable abrasives may leave random scratches or cause uneven material removal, requiring additional labor to correct. Green abrasive film provides stable performance, lowering the likelihood of:

-

unexpected deep cuts

-

patchy surface refinement

-

scattered scratch depths

-

over-sanding or under-sanding

The result is smoother workflow continuity and improved throughput.

Compatibility With Both Manual and Machine Sanding

Green abrasive film accommodates a wide range of finishing tools:

-

orbital sanders

-

pneumatic finishing systems

-

hand sanding blocks

-

automated robotic sanding platforms

Its flexibility and structural stability make it suitable for complex geometries such as curved molded parts, beveled edges, or contoured metal surfaces.

Conclusion

Green abrasive film has become an essential material for achieving high-precision surface finishing across a wide range of industries. Its micro-engineered grains, stable polymer backing, controlled cutting dynamics, and compatibility with both manual and automated systems make it a dependable choice for professionals seeking predictable and efficient finishing performance. Products such as the Golden Abrasives green abrasive film exemplify how modern abrasive films can deliver stability, uniformity, and long-term reliability in demanding production environments.

http://www.goldenabrasives.com

China Golden Abrasives -

-

AuthorPosts

- You must be logged in to reply to this topic.